In the realm of metalworking, surface treatment is an indispensable step. It not only enhances the aesthetics of the products but also significantly improves their durability and performance. Shuopu offers a variety of surface treatment services, including sandblasting, powder coating, manual painting, and robotic painting. Let’s delve into these methods and explore their applications and advantages across different industries.

1. Sandblasting: The Preferred Choice for Cleaning and Surface Preparation

Sandblasting is a technique that uses high-speed streams of abrasive particles to clean and roughen metal surfaces. It is commonly used to remove rust, old paint, and surface contaminants, providing an ideal surface for subsequent coating or welding operations.

Advantages:

- Efficient Cleaning: Quickly and effectively removes rust, oil, and other contaminants.

- Surface Roughening: Enhances the adhesion of subsequent coatings or welds, ensuring a more robust bond.

- Versatility: Suitable for a wide range of metal shapes and sizes, adaptable to various needs.

Typical Applications:

- Naval Architecture and Marine Engineering: In preparing hulls and marine platforms, sandblasting ensures coatings adhere well, preventing corrosion from seawater.

- Chemical Industry: Cleans tanks and pipelines, removing residues and old coatings to provide a clean base for new applications.

- Mining Industry: Used to clean mining equipment surfaces, removing mineral deposits and dirt, extending equipment lifespan.

2. Powder Coating: The Eco-Friendly Protective Barrier

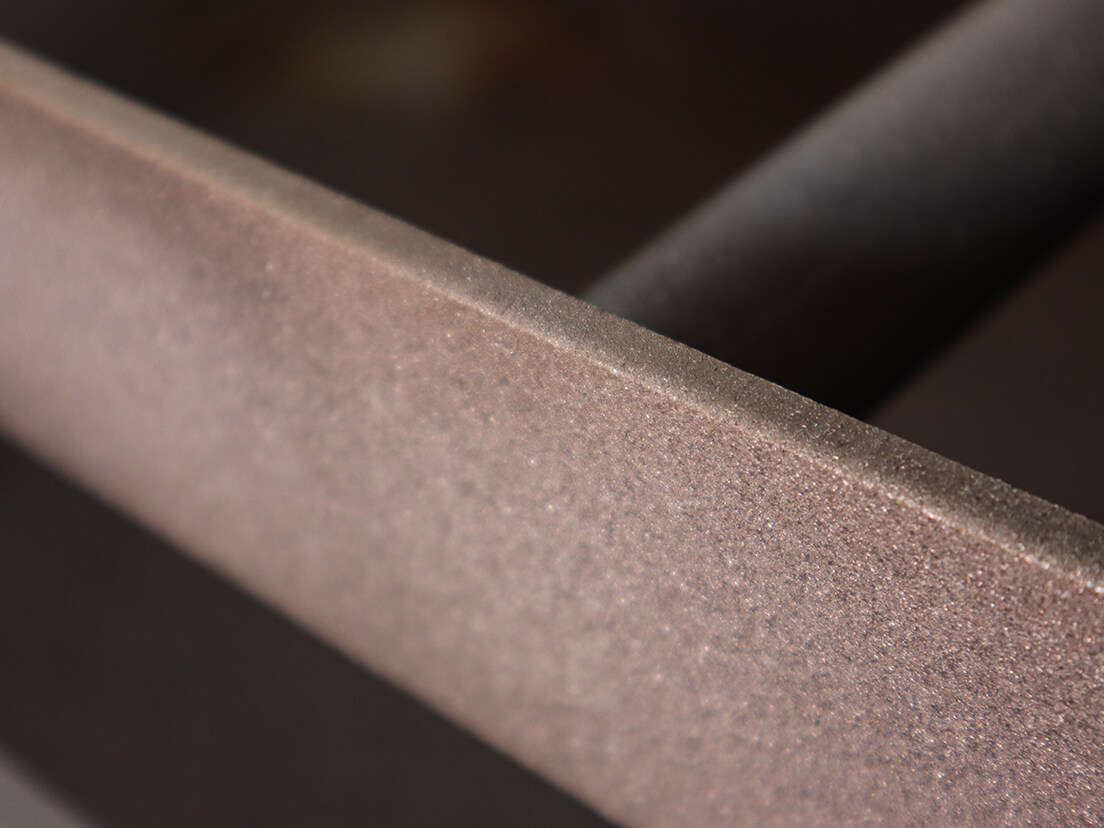

Powder Coating is a solvent-free coating process that uses electrostatic application to spray dry powder onto metal surfaces, which is then cured at high temperatures to form a smooth and durable protective layer.

Advantages:

- Eco-Friendly: Free from solvents, reducing environmental impact.

- Exceptional Durability: Provides uniform, wear-resistant, and corrosion-resistant coatings that offer long-term protection.

- Variety of Colors and Textures: Offers a wide range of color and texture options to meet diverse aesthetic and functional requirements.

Typical Applications:

- Industrial Automation Systems: Powder coating protects control cabinets and other key components, ensuring their functionality and appearance in harsh industrial environments.

- Construction Industry: Applied to external decorative elements and building components, offering weather resistance and lasting decorative effects.

- Oil & Energy: Provides corrosion-resistant coatings for drilling equipment and pipelines, maintaining performance in extreme outdoor and underground environments.

3. Manual Painting: The Delicate Craft of Traditional Techniques

Manual Painting is suitable for products with complex shapes and requiring precise control in small batches. Skilled craftsmen use brushes, spray guns, or other tools to meticulously apply paint to metal surfaces.

Advantages:

- High Flexibility: Suitable for metal surfaces with complex shapes or requiring detailed handling.

- Unique Textures: Can achieve rich visual effects and textures, catering to personalized demands.

- Adaptability: Ideal for small-batch and customized production, allowing precise treatment according to specific requirements.

Typical Applications:

- Precision Instruments: In surface treatment of high-precision instruments, manual painting provides unparalleled detail and precision.

- Construction Details: Applied to complex building elements and decorative items, enhancing the aesthetic appeal and durability of buildings.

- General Machinery & Equipment: Ideal for custom machine parts, ensuring every detail meets high surface treatment standards.

4. Robotic Painting: The Perfect Combination of Efficiency and Precision

Robotic Painting employs industrial robots for automated spraying operations. This method is particularly effective in large-scale production, ensuring consistent quality and high production speed.

Advantages:

- High Precision: Delivers precise and consistent coatings with minimal errors.

- High Efficiency: Can complete large volumes of painting tasks in a short time, suitable for mass production.

- Safety: Reduces manual operation, minimizing health and safety risks during the process.

Typical Applications:

- General Machinery & Equipment: Ideal for large-scale automated painting of mechanical components, ensuring high-quality and consistent surface treatments.

- Industrial Automation Systems: Provides high-precision coatings for mass-produced automation system components, ensuring long-lasting durability.

- Naval Architecture and Marine Engineering: Used for large-scale painting of ships and marine platforms, offering long-lasting corrosion protection in harsh marine environments.

Choosing the right surface treatment method depends on various factors, including the product's application, material properties, and environmental conditions. Whether it’s to enhance durability, improve appearance, or meet specific technical requirements, Shuopu is equipped to provide professional solutions. If you have any questions or would like to learn more about our services, please do not hesitate to contact our team.