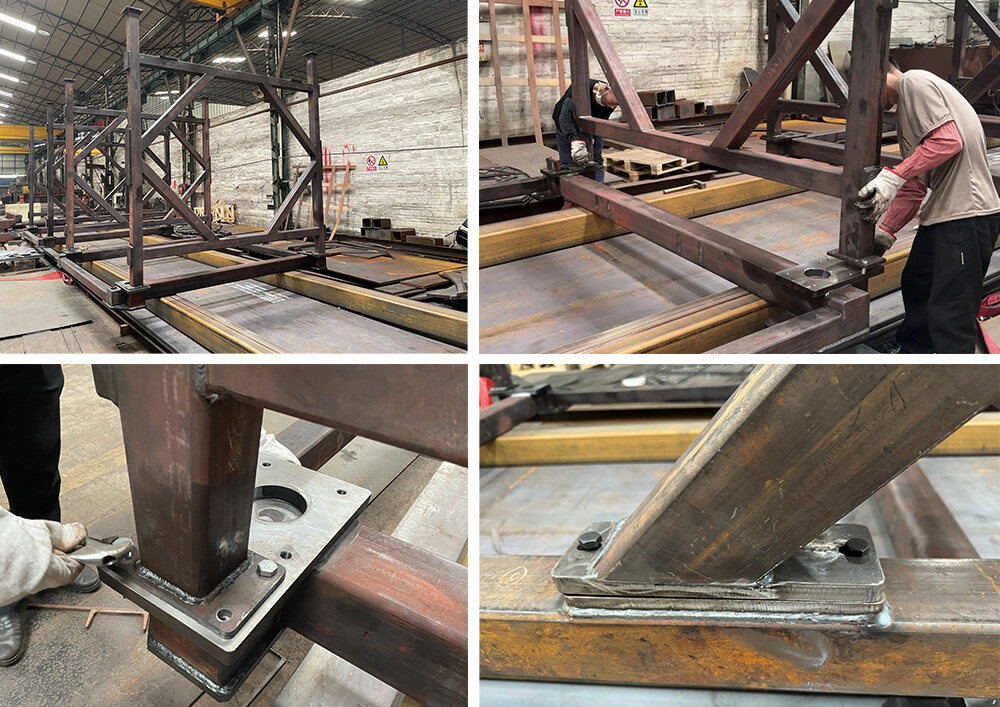

At Shuopu Machinery Technology, we recognize the importance of pre-assembly and integrate it as a core step in our production process. This fundamental stage ensures that each component is meticulously crafted and tested, laying the foundation for a high-quality final product.

In the manufacturing of packaging machinery, pre-assembly is a crucial step. It not only helps ensure the efficient operation of the equipment but also saves significant time and costs during the final assembly and installation phases.

What is Pre-Assembly?

Pre-assembly refers to the process of assembling part or all of the components of mechanical equipment prior to final assembly and installation for preliminary functional testing. This aims to identify and resolve potential issues, ensuring that each component can seamlessly integrate into the final equipment.

Importance of Pre-Assembly

- Improved Accuracy and Quality

Pre-assembly allows us to conduct detailed inspections and adjustments in a controlled factory environment, ensuring the dimensions and fit of each part are precise.

- Reduced Installation Time

Time is often a critical factor during equipment installation at the customer's site. By utilizing pre-assembly, we can significantly reduce the complexity and time required for on-site installation.

- Cost Reduction

Pre-assembly helps us identify potential design flaws or manufacturing issues, preventing additional costs associated with rework or modifications. By making adjustments in the factory, we ensure the final performance and quality of the equipment while lowering costs.

- Enhanced Customer Satisfaction

Through pre-assembly, we can conduct comprehensive testing of the equipment before delivery, ensuring it meets customer expectations.

Pre-assembly is an indispensable part of the packaging machinery manufacturing process. It not only enhances the precision and quality of the equipment but also saves time and costs, ultimately delivering greater value to our customers. As a professional machinery manufacturer, we are committed to incorporating this critical step in our production processes to ensure that every delivery operates reliably and efficiently on our customers' production lines.